Industry 4.0 is a concept that refers to the fourth industrial revolution, characterized by the integration of advanced and digital technologies in the industrial environment. It is a set of transformations and innovations that seek to create smart and efficient factories, promoting greater automation, connectivity and information exchange between machines, systems and human beings.

This industrial revolution is driven by the combination of various technologies, such as the Internet of Things (IoT), artificial intelligence (AI), big data, cloud computing, additive manufacturing (3D printing), among others. These technologies are combined to create a highly connected and intelligent industrial infrastructure. Here’s a look at each of them and their applications in Industry 4.0.

Internet of Things (IoT)

The Internet of Things (IoT) plays a key role in Industry 4.0, enabling connectivity, communication and data exchange between physical devices, machines and objects in industry.

One example is connected devices and sensors, used to monitor and control production processes in real time. These sensors can measure variables such as temperature, pressure, humidity and fluid levels, among others. Based on the data collected, automated control systems can adjust and optimize process parameters, ensuring production quality and efficiency.

Cloud computing

The operational processes of the 4.0 era require greater sharing of data between devices, software and users, which is why cloud computing plays an important role in allowing access to data in real time without the need to invest in local infrastructure. It facilitates the sharing, management and processing of information between different users and has the capacity to store large amounts of data, promoting greater accessibility, collaboration and efficiency.

Augmented reality

Augmented reality is the name given to an interactive experience that combines the real world and computer-generated content. It can be applied, for example, to training employees before they carry out their duties in practice, a part that can be assembled virtually, step by step, until the employee is able to carry out the process. Or even in the maintenance of complex machines, which require specialized employees who don’t always work full-time. In cases of emergency maintenance, a specialized technician can do it remotely or guide another employee on site.

Artificial Intelligence (AI)

Artificial intelligence (AI) has a wide range of applications in Industry 4.0, capable of recognizing patterns and making decisions based on algorithms. It can be applied in predictive maintenance, for example, by analyzing sensor data and information on the performance of machines and equipment to predict failures and problems before they occur. This enables predictive maintenance, where interventions are carried out based on advanced analysis, minimizing unplanned downtime.

It can also be applied to image analysis and computer vision to carry out automated visual inspections. For example, AI algorithms can identify defects or anomalies in products during the manufacturing process, reducing the need for manual inspection and improving quality.

These are just a few examples of how it can be used in Industry 4.0 to provide advanced automation, real-time data analysis, process optimization and improved operational efficiency.

Cybersecurity

Industrial cybersecurity is an extremely important issue today, especially when it comes to protecting data and processes, since in Industry 4.0 all areas and systems end up interconnected, whether via the internet, a cloud service or even with some connection to the outside world. All this decentralization of information opens up security gaps that didn’t exist before, making it an ever-increasing necessity within companies.

Implementing measures to increase data protection in various scenarios, especially where several people have access, is becoming necessary and some examples are access control, digital signatures, connection isolation and periodic network monitoring. Another possibility is the integration of artificial intelligence and cybersecurity. With AI’s ability to analyze and interpret data, it is possible to automate processes to check for cyber attacks, making the digital environment even safer.

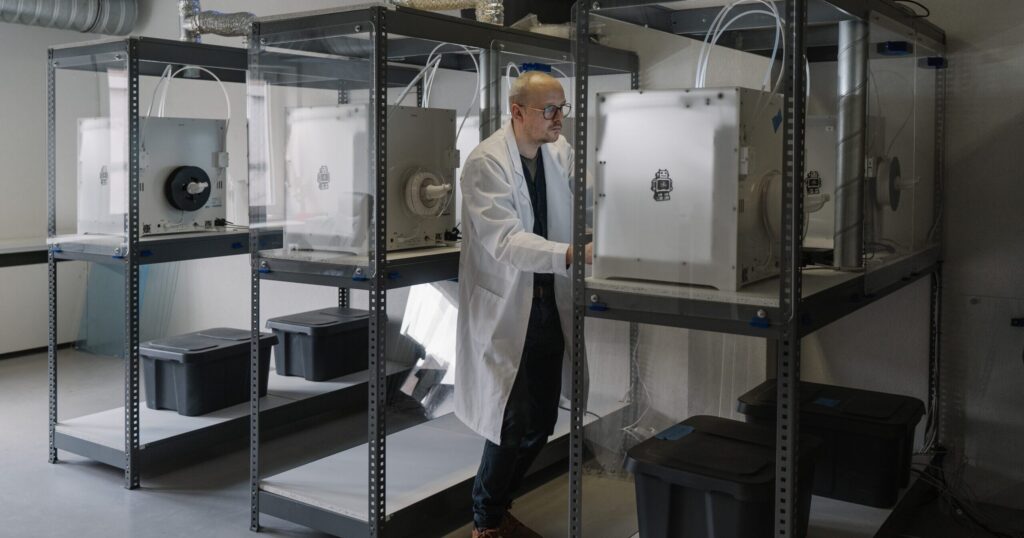

Additive manufacturing

Additive manufacturing, also known as 3D printing, produces parts from a digital model, which is transformed into a three-dimensional object as the raw material is added one layer at a time. Additive manufacturing can bring several benefits, such as cost savings, since the raw materials used in additive processes are usually cheaper than those used in traditional processes. Another important point is sustainability, since the process uses fewer materials, avoiding waste and benefiting the environment.

Big data

This integration and connectivity between machines and industrial systems makes it possible to collect and analyze large volumes of data, known as big data. This data is processed and used to gain valuable insights into process efficiency, identify faults or anomalies, predict problems and optimize production.

Final considerations

Although it’s not new, the term Industry 4.0 is still fairly unknown here in Brazil. However, according to experts, adherence to the 4.0 era should happen gradually and in 10 years, it’s estimated that 15% of companies in the manufacturing sector will already have this concept embedded in their activities.

Roboflex offers complete factory solutions that make it possible to install hardware with greater dynamism to turn them into smart factories. By integrating the tablet with the ecosystem of machines, sensors and monitoring devices, we can promote greater connectivity via wireless or even wired networks.

This allows the user to track all information in real time, such as production order notes, technical product information queries, work instructions, machine performance and condition to identify imminent faults and schedule maintenance, track the location and status of products in real time throughout the production and logistics chain, allowing precise stock control, quick identification of items and optimization of material flow.

Roboflex products also adhere to the industry ecosystem, resisting the weather and other particularities of the operation.

Discover our solutions to make your factory smarter!